You will learn how to determine the material of mold in this chapter.

The material of the mold is determined depending on usage.

Material Criteria

The criteria to determine the material of a mold includes the following:

– Abrasion Resistance

Consider how long a mold will last or if parts will accurately maintain their dimensions depending on production quantity.

– Polishing

Consider how much a mold should be polished for the desired part finish.

– Machinability

Use a solid material that can process mold or parts good.

– Heat Treatability

Use a material that can be processed evenly by heat treatment.

– Durability

Use a material that is durable against pulling stress, compression stress, or bend stress during the molding process.

– Heat Conductivity

Use a material whose temperature can be easily controlled while cooling the mold.

– Delivery / Cost

Use a low cost material that is easy to get in the market as well as delivered securely and immediately. With these conditions considered, determine a material.

Types and Use of Material of Mold

The following steel materials are generally used for a mold. The different components of a mold require different materials. Furthermore, some components have special hardness requirements and require the material to be heat treated.

Rolled Steel for General Structure (JIS symbol: SS400)

Advantage: Low cost and easily obtained.

Disadvantages of this material is that it is soft and has many pinholes (air bubble holes). It is used for parts that do not require strength or hardness (ejector plate, spacer block, support pillar).

Carbon Steel for Machine Structure (JIS symbol: S25C – S55C)

Advantage: Low cost and easily obtained. High in quality. Used for normalizing, or with quenching, or tempering.

- (A) S35C – S45C

Widely used for general attaching mold parts, support plate, locating ring, or sprue bush. - (B) S55C

Used with quenching and tempering to HS28 – 35 hardness to improve the quality. This is widely used as the most standard mold material.

Carbon Tool Steels (JIS symbol: SK3 – SK7)

Quenching hardness is high (HRC50 – 60). Excellent in abrasion resistance and relatively low cost tool steel.

Used for sliding parts that require hardness and abrasion resistance such as guide pin, guide bush, or return pin.

Alloy Tool Steels (JIS symbol: SKD, SKS)

- (A) SKD11

Superior in quenching and abrasion resistance to SK material. Generates little burn bending. Used for cavity and core (insert), and hardness is HRC55 – 60. Sometimes other steels such as abrasion resistance uniform steel or steel for hot-work are used. - (B) SKD61

Excels in heat resistance and toughness. Used for cavity and core (insert) that require hardness and abrasion resistance. When used for ejector pin, nitriding is performed to harden the surface. - (C) SKS2, SKS3

Steels improved in quenching and abrasion resistance by adding chrome and tungsten to carbon tool steels and quenching. Used for cavity and core (insert) that require hardness and abrasion resistance. Hardness is HRC55 – 60.

The chart below shows the steels that are used as a mold plate material. As requirements for each mold vary depending on part material, finishing of part, or reinforcement and filler such as glass fiber mixed in a molding material , it is important to use material that meets each requirement.

Proper Steel for Major Resin (by manufacturer)

Major Resin |

Major Products |

Required Feature |

Proper Steel |

|||

Hitachi Steel |

Daido Steel |

|||||

General |

General |

Polyacetal Polypropyrene Polystyrene Polyamide (Nylon) ABS |

Bumper |

Machinability |

HPM7 HPM1 FDAC HPM31 |

NAK55 DH2F PD613 |

Texture |

Texturing |

|||||

Transparent |

Methacrylic resin |

Stereo dust cover |

Mirror finishing |

HPM50 |

NAK80 |

|

Glass Fiber Filled |

Polycarbonate polyamide (Nylon) ABS Polystyrene |

Electric parts |

High abrasion |

+ surface finishing HPM31 |

+ surface finishing PD613 |

|

Phenol Epoxy Polyester |

DAC HAP10 HAP40 HAP72 |

DHA1 DEX20 DEX40 DEX80 |

||||

Heat Treatment of Material

The mold material is either processed without treatment or is used with heat treatment or surface finishing to improve the quality of steel.

Heat treatment is performed to improve the quality of the entire steel.

Surface finishing is performed to improve only the quality of surface but maintain the original material quality inside.

Heat Treatment of Steel Material

The heating or cooling treatment of metallic material to add required hardness, abrasion resistance, or machinability is called heat treatment.

Heat treatment consists of four tasks – quenching, tempering, normalizing, and annealing.

1) Quenching

Steel material is first heated to a high temperature, and then rapidly cooled down by water or oil.

This procedure increases hardness of the steel material. However, if the steel contains less than 0.3% or more than 0.6% of carbon, the procedure is not effective.

2) Tempering

The quenched steel material is heated and cooled again.

This is done to add persistence to the steel material, but its hardness will decrease a little from that of the quenched steel.

3) Normalizing

The steel material is heated to a certain temperature, and then air cooled after being kept at that temperature for a certain period of time.

This procedure is done to refine crystal of cast steel (rough structure and poor mechanical function) or forging steel, improve and normalize the material quality.

4) Annealing

The steel material is heated to a certain temperature, and then cooled gradually after being kept at that temperature for a certain period of time.

This is done to remove deficiencies of the steel material that cause undesirable conditions, such as structure distortion, oversized coarse crystal, hardening by process.

Surface Hardening of Steel Material

1) Cementation

Carbon is soaked in the surface of the material to create a steel layer.

2) Nitriding (Tufftriding)

After quenching and tempering, the steel is nitrided by being heated to diffuse nitrogen.

This method makes a layer of iron nitride on the surface harder than the cementation process.

3) Cyanide Process

First, cyanide is heated to a certain temperature in an iron container to be molten. Then steel is soaked in the molten cyanide and cooled rapidly by water or oil to increase hardness.

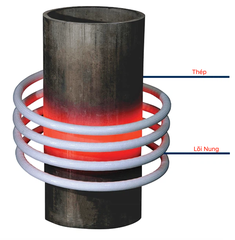

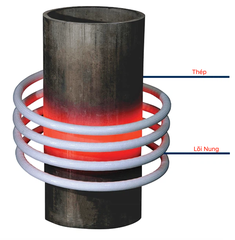

4) Induction Hardening

The method of quenching by the heat from eddy current which is generated by high frequency current. Working time is short, and quenching is made evenly.

Phương pháp nung cảm ứng